This swatch brings together Taiwanese local craftsmanship and DIY electronics manufacturing to etch conductive textiles and create flexible PCB. The goal of this experiment is to etch away copper from a conductive textile to make a flexible circuit or a flexible sensor by combining PCB (printed circuit board) etching and rice paste resist traditionally used in Taiwan for indigo and natural dyeing. Rice paste resist is also known as Katazome in Japan.

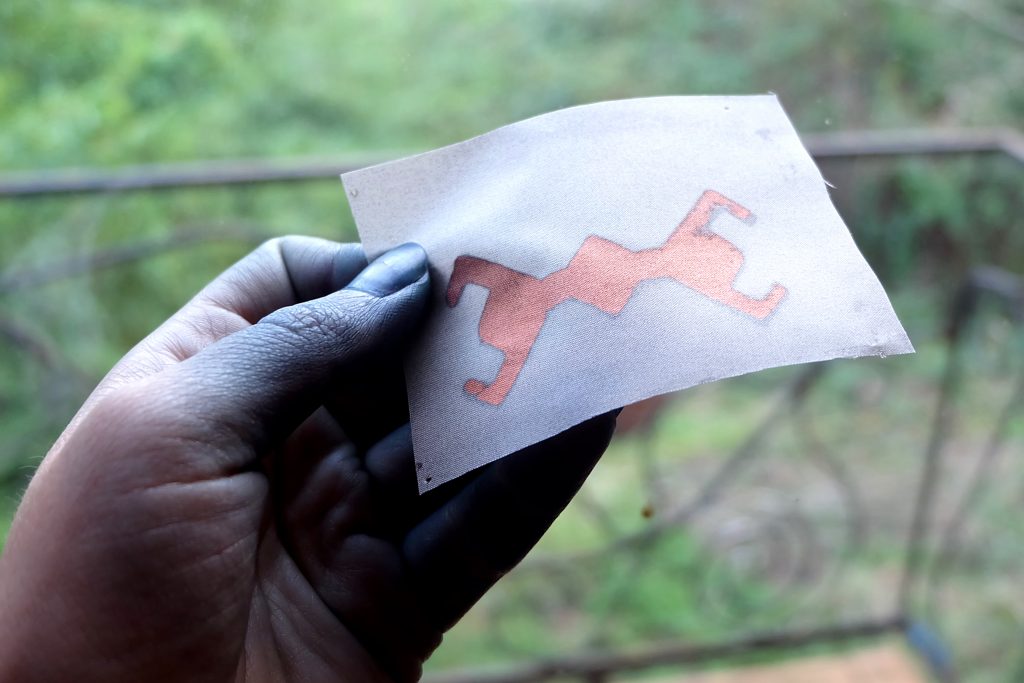

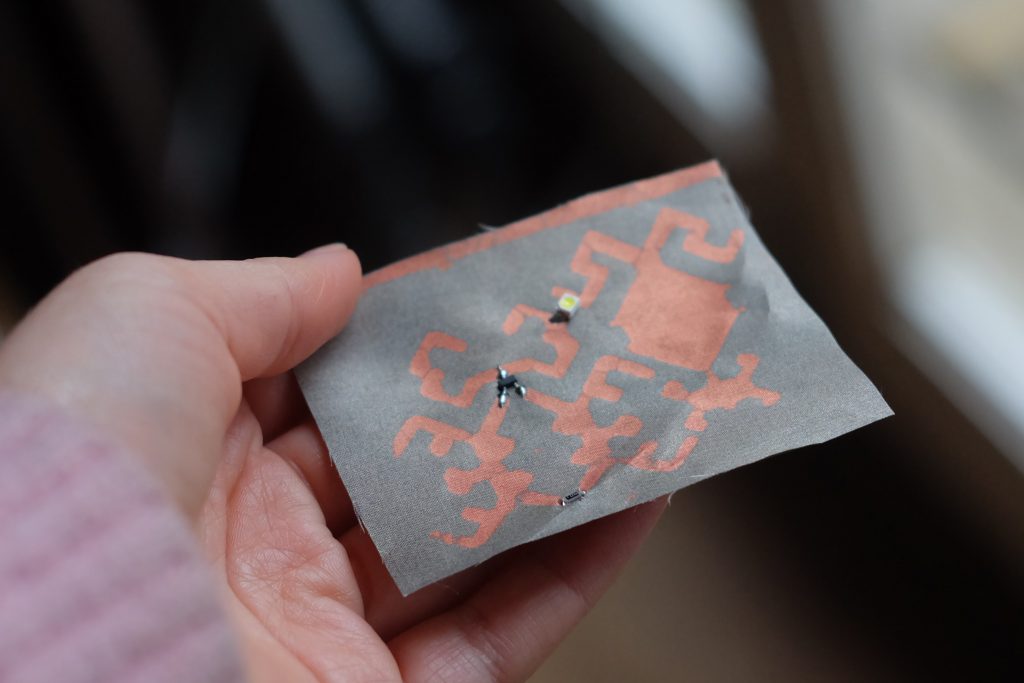

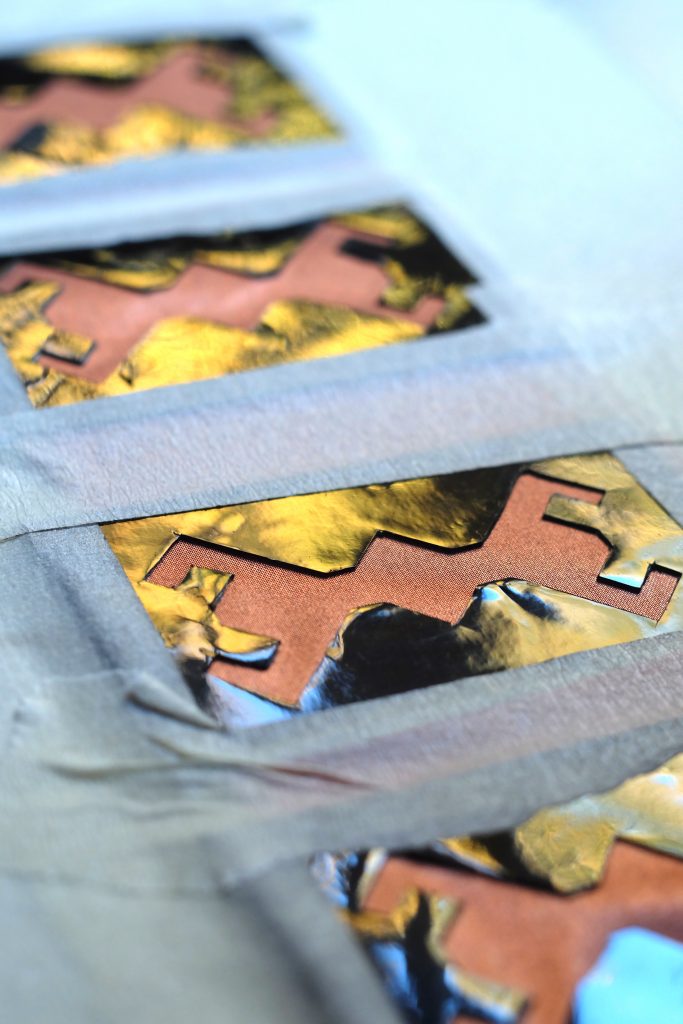

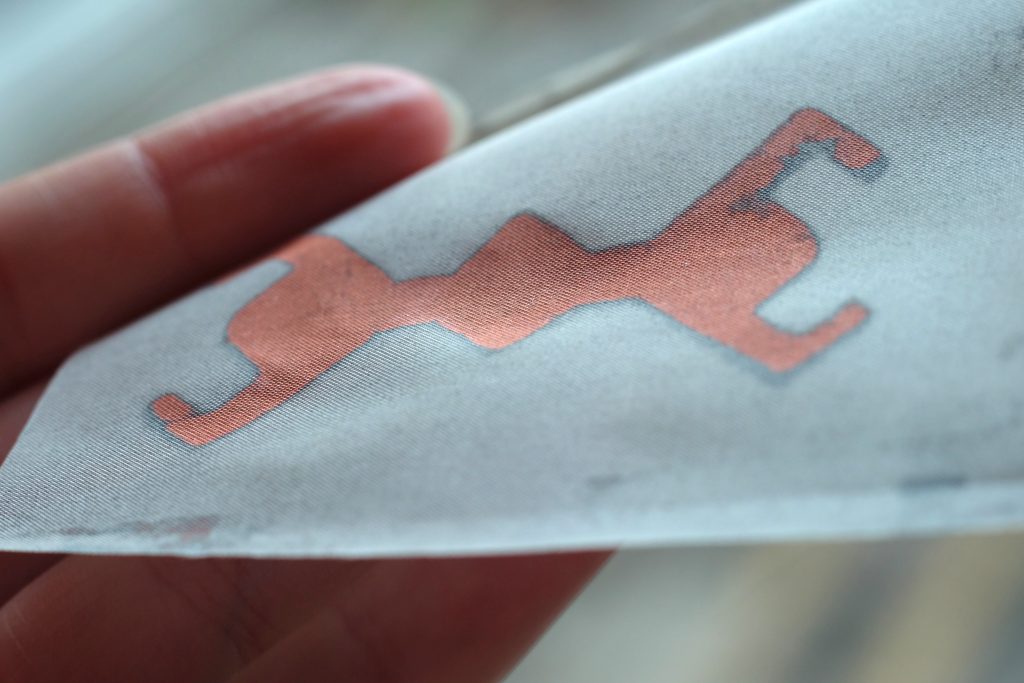

The rice paste will create a mask which will protect the conductive properties of the conductive textiles following a custom-made shape. The rice paste resist is commonly apply using a stencil, here the shape is made using a double-side stencil made of vinyl. The textile and its mask are then immersed in a etch bath made up of salt, oxygenated water 10 volumes (aqueous solution composed by 3% of hydrogen peroxide) and vinegar. At the end of the process, the uncovered parts of the textile will have lost their conductive properties and the conductive circuit, protected by the the rice paste will remain on the textile; this technique permits to preserve the textile subtract. To create this swatch, various recipes of rice paste resist have been experiment and several conductive textiles have been compared to find the perfect match : a textile which will quickly be etched before the rice paste resist could start melting.

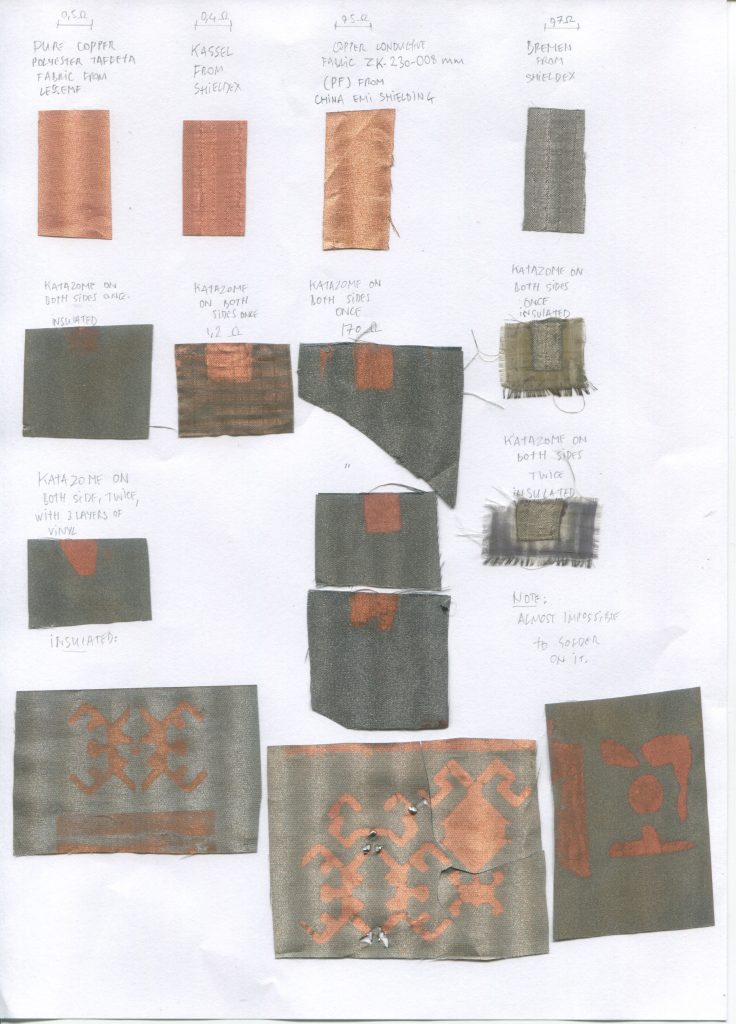

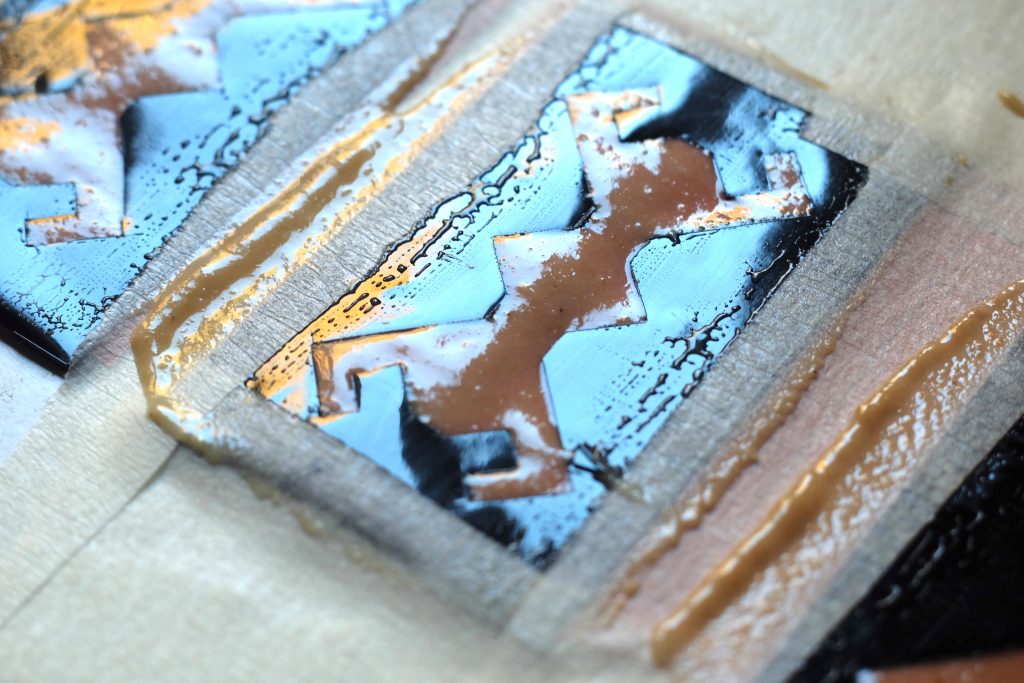

All conductive textiles are different and will not react in the same way in the etch bath. To avoid the rice paste resist to melt during the etching process, it requires to select a textile which will quickly react and lose its conductive properties. Four conductive textiles have been compared: Bremen from Shieldex, Pure Copper Polyester Taffeta Fabric from LessEMF, Kassel from Shieldex and Copper Conductive Fabric ZK-230-008mm (PF) from China Emi Shielding. These textiles have been immersed in etch baths during different times, dried and tested with a multimeter to mesure their conductivity. Bremen from Shieldex is the quicker to etch but is not suitable for soldering. Kassel from Shieldex, due to its weaving, is difficult to etch. Copper Conductive Fabric ZK-230-008mm (PF) from China Emi Shielding seems to quickly etch but its grey aspect reveal a persistent conductivity. The best results have been obtained with the Pure Copper Polyester Taffeta Fabric from LessEMF, with which the etching process is longer to start but the exposed textile starts to be insulated after only 15 minutes in the bath. If the bath is prolonged, after 55 minutes a white textile substrate appears.

This swatch has been made in France by Audrey Briot following instructions and advices on rice paste resist given by Lien Wei Ti. If the swatch is meant to use Taiwanese local ressources, rice bran was difficult to find in France. Experiments using tapioca starch, white rice flour and glutinous rice flour shown that rice bran is a key ingredient to make rice paste resist and can not be substituted.

Step-by-step:

The rice paste resist :

The rice paste resist has been made following this recipe recommended by Lien Wei Ti.

Mix 1 volume of water with 1 volume of glutinous rice flour and 1 volume of rice bran (stabilized rice bran in my case, but komon-nuka, defatted rice bran is recommended). You might obtain a dough soft like your earlobe. Then, shape it in one or several doughnut forms, place them in a textile and put them in a steamer for 30-40 minutes. Once the steaming is done, strain the dough, if needed, add up to 20% of water. Add 20% of water to the strained dough and knead.

The stencil :

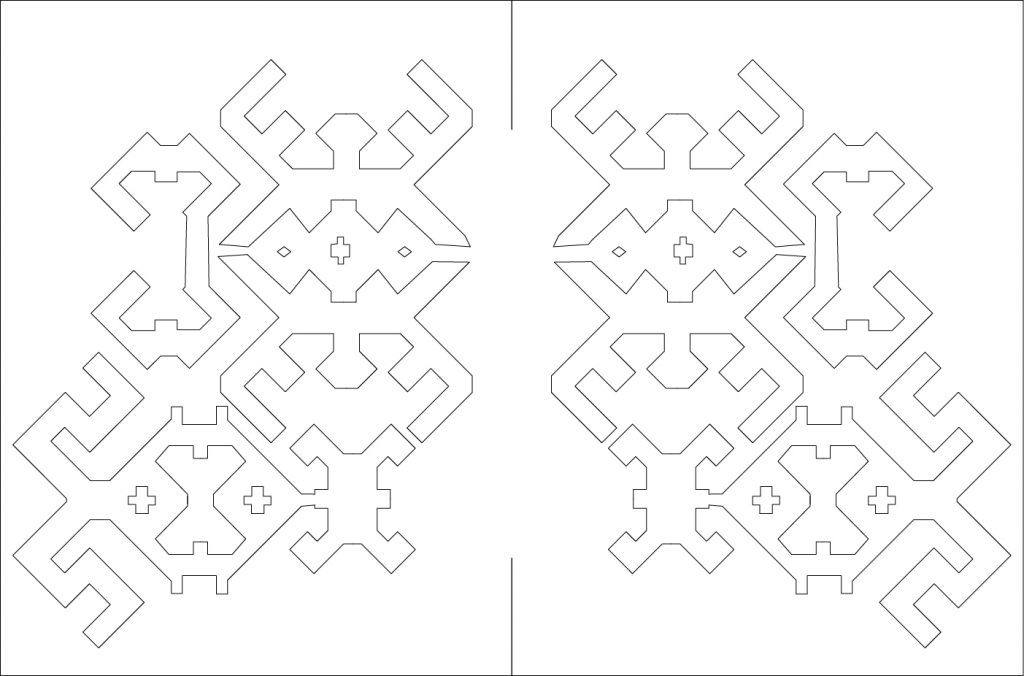

The rice paste needs to be applied on both side of the textile. Also, the thickness of the stencil will influence the thickness of the rice paste resist. In this swatch, 3 layers of vinyl have been stacked. You can cut your stencil by hand or by using a vinyl cutter. In both case, remember to make the same shape in mirror. By hand, fold your vinyl and cut both side at the same time. With a vinyl cutter, make sure to make the same shape in mirror.

Set up your textile (Pure Copper Polyester Taffeta Fabric from LessEMF) between the two layers and tape their sides on a table.

Apply the rice paste with a squeegee or a credit card. Make sure the stencil thickness is full of paste. Let it dry slowly. Once dry, with you see the rice paste is not thick enough, apply some for a second time or a third time. When it is totally dry, do the same thing on the back side. When both sides are dry, remove the stencil.

The etch bath :

Use ustensils which are only dedicated to etching. Mix 2 volumes of salt, 3 of oxygenated water 10 volumes (aqueous solution composed by 3% of hydrogen peroxide) and 4 of white vinegar (10% acidity in my case). The textile is immersed in the etch bath for 15 to 55 minutes. After 15 minutes, the uncovered parts of the textile are insulated, even if they look grey. The textile can stay in the etch bath until the rice paste resist doesn’t melt, after 55 minutes in the bath, the white polyester substrat appears.

Let the textile dry. Once it is dried, use a multimeter to mesure the textile’s conductivity. The circuit should have kept its initial conductivity which is 0,5 Ohm/cm. Everything outside of the circuit should be insulated.

To improve the process, use hydrogen peroxyde in an higher concentration.

Related works :

– Salt and vinegar etching, Kobakant

– Workshop Batik and Copper fabric etching, Workshop Leaders: Mili Tharakan and Hannah Perner-Wilson during E-Textile Summercamp 2013, using batik.

– Interdigitation for the eTextile matrix sensor, Maurin Donneaud, Cedric Honnet, Audrey Briot, in E-Textile Swatch Exchange 2017 using lard as a mask for etching conductive textile;

– Sensing Dripping, Martin De Bie, in E-Textile Swatch Exchange 2017 using vaseline;